The reality today is that it’s virtually impossible to design a system which is totally immune from in-service deterioration or corrosion. So the question becomes the following: how do operators extend the length of time before a maintenance shutdown and perform a repair the most effective way for the best return on investment while minimizing downtime?

MCOR can effectively lengthen the life cycle of your pump and flow system. Our advanced coatings and repair polymers diminish the costs associated with the different stages of a pump’s lifecycle. With repair, rehabilitation and high performance protection, you’ll be able to incorporate an extremely cost effective preventative maintenance program that will ultimately reduce both downtime cycles and man hours while increasing efficiency and performance.

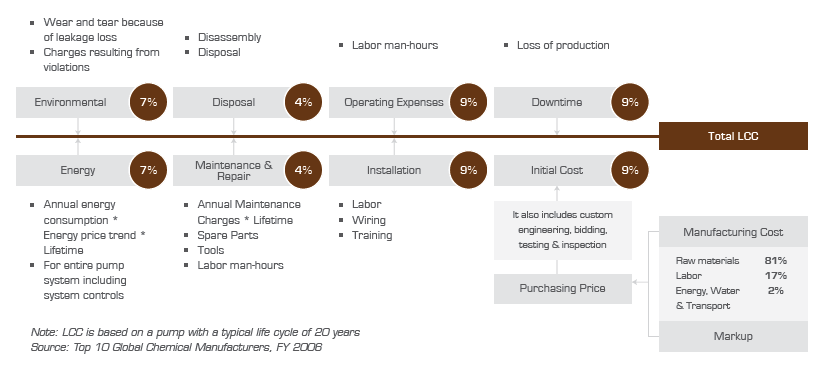

WHY LIFE CYCLE COSTS (LCC) MATTER

LCC is the total cost associated with an industrial pump from the point of procurement up to the point of decommissioning and disposal of the installed pumping system.

It is an important tool to help plant managers choose between alternative resources and decide between repairs versus a new purchase.

The purchasing price is only a small part of the total LLC of any

industrial pump, but other operating costs- such as maintenance, repair and energy account for nearly half of it.

Most pump users make procurement decisions based on the initial

purchase cost, which is often only 10 percent of the total LCC.

Organizations with a ROI focused management do not purchase pumps based on their initial purchase and installation costs. Instead, they focus on the total LCC of a pump, which is five times greater than the initial expense and installation costs.